Ethylene Vinyl Acetate (EVA)

Exploring Ethylene Vinyl Acetate (EVA) and Its Diverse Applications

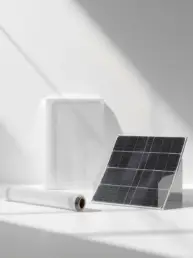

Ethylene Vinyl Acetate (EVA) is a highly versatile and adaptable polymer that has established a strong presence across multiple industries. Known for its rubber-like flexibility, toughness, and resilience, EVA has become a material of choice for manufacturers seeking both performance and cost-effectiveness. From packaging films to solar encapsulants, EVA is shaping modern manufacturing in ways that often go unnoticed

Footwear & Apparel: EVA is commonly used in shoe soles, slippers, sandals, and flip-flops, offering exceptional cushioning,

Packaging & Films: Widely applied in food-grade wraps, laminated sealing films, and protective packaging, EVA ensures strong thermal sealing flexibility.

Automotive Components: Used in car interiors, floor mats, trims, dashboards, and sound-dampening elements to enhance comfort, reduce noise

Medical & Healthcare: Essential for IV bags, tubing, soft cushions, sterile packaging, and various disposable medical products due to its safety

Solar Energy: EVA sheets act as reliable encapsulants in photovoltaic (PV) solar panels, providing UV resistance, strong adhesion, and long-term stability.

Sports & Recreation: Found in yoga mats, exercise mats, sports padding, protective equipment, and flotation devices for its shock-absorbing properties.

Consumer & Household Goods: Used in furniture padding, toys, soft stationery, foam sheets, and general household cushioning.

Construction & Industrial Uses: Applied in adhesives, insulation sheets, and flexible foam components for better thermal and sound performance.

CredcoSourcing supplies high-quality virgin Ethylene Vinyl Acetate (EVA) granules engineered for precision and consistency across a wide range of industries. Renowned for their lightweight strength, excellent stiffness, and superior moldability, these granules are ideal for producing containers, trays, buckets, toys, furniture parts, and automotive components.

Our virgin EVA deliver consistent flow, outstanding impact resistance, and exceptional chemical stability, ensuring efficient processing and reliable end-product performance. We also offer customized MFI (Melt Flow Index) and a variety of color options tailored to match your specific production requirements.